For an investor of large-scale solar PV power plants, efficiency and reliability are two of the most interesting issues. For rating purposes, the Performance Ratio (PR) factor, has been created. However, this metric is only suitable for comparisons to a limited extent, argues Edwin Cunow, owner of LSPV Consulting.

It quantifies, among other things, the overall effect of losses that occur during the operation of a PV plant. It also monitors plant operations and the power degradation of the PV generator/modules.

The PR Factor is a dimensionless term describing the power ratio of real produced energy (final yield Yf) and a calculated reference energy quantity (reference yield Yr) within a defined period. The optimal period is one year so as to offeset typical seasonal ups and downs of PR over the year. On demand PRs for shorter period values are possible.

The PR is independent from the installed capacity and location of a PV plant. That is why it can be used to compare the performance of PV plants located anywhere in the world. This article calls into question whether this statement is valid in all cases.

At first glance, the PR Factor is simple to calculate: PR = Yf / Yr. The comparison of PRs to one another with other PV plants is, however, not that simple. Various obstacles are described in the following:

The calculation refers to nominal / reference energy yield Yr. Yr is the total in-plane insolation H divided by the PV plants’ reference insolation G. It stands for an equivalent number of hours at the reference insolation, whereas G is equal to 1 kW/m. Yr then is the number of peak hours of sun or the solar insolation in units of kWh/m². Yr = H/G [kWh/m² /1 kW/m²] in hours.

It considers real measured insolation at the PV plant, the nominal power (sum of nominal power of all installed PV modules) of the plant and the nominal PV module efficiency (usually data sheet value, EN 50380), as set out in the contract. The nominal module efficiency refers to the Standard Test Conditions (STC) defined in standard IEC 61215. According to the Standard Test Conditions: 1 m² aperture, and 1,000 W/m² insolation with a standard spectrum at 25° cell temperature. In the course of a year, STC conditions appear only in the event of short hours, values are mostly below or sometimes above. Essential influences have local ambient temperatures and such conditions as wind.

Final yield Yf is the sum of AC energy produced and fed into the grid in a calendar year. It has to be read from the referring feed-in energy counter divided by the nameplate DC power of the PV generator at STC conditions Yf = kWh AC / DC kWp. It stands for the number of hours that the PV plant would need to be operated at its nominal power to produce the same energy.

Why are investors interested in the performance information of other PV plants? At first glance, a PR comparison is predestined for this. Through benchmarking it is possible to draw conclusions for the assessment of the plant with regard to quality, efficiency and reliability.

The author has more than 30 years of experience in PV, with more than two decades as a consultant exclusively in MW projects. During that time, LSPV Consulting gathered conflicting evidence, which questions the PR comparisons of plants.

What makes PR comparisons difficult?

Considering influencing factors, engineers differentiate between non-influenceable and influenceable PR loss factors in their calculations. Non-influenceable factors are main hardware components, like referring to PV module losses, by temperature coefficient, inverter and transformer losses, for example. But how should grid circumstances like brownouts and blackouts be treated in this concern? Should PR calculations consider grid failures, voltage and frequency deviations out of the given range? As these circumstances are outside the responsibility of the PV plant itself, they should not be part of a PR calculation.

Very well influenceable are other design features like loss factors from the tilt of PV modules, and row-to-row shading, as well as DC and AC losses from cabling, diodes, contact resistances and – to a certain extent – by the selection of inverters and transformers.

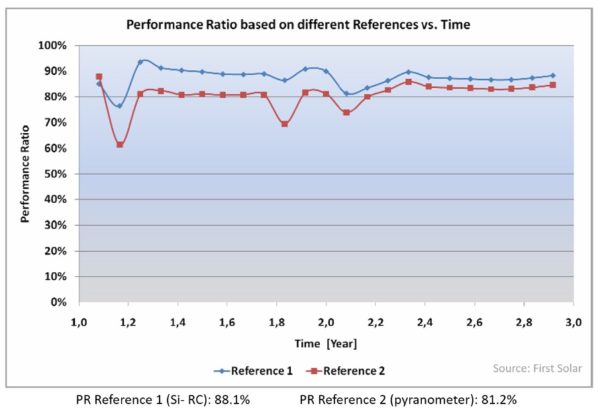

Furthermore, the kind of component for measuring the insolation reference plays an important role. As seen in many plants in the MW range, pyranometers as well as reference cell/reference modules in other plants are in use. As will be shown below, it makes a significant difference regarding PR comparisons.

Reference cells or pyranometers

As early as the 1980s, the question of which solar radiation device should be applied for the PR calculation arose on the German PV scene. Discussed were the reference cell RC resp., Reference Module RM or pyranometer as reference elements. The RC/RM was ultimately identified as the appropriate sensor. It should use the same cell technology as is applied modules in this field. Argument: RC/RM should have the same spectral density as applied PV modules in the plant. Pyranometers measure solar irradiance with a much wider spectrum; they are measuring the global irradiation on site of the plant.

Over the course of time, international standards have confirmed this. As an example, IEC 60904 Photovoltaic Devices – Part 2: Requirements for photovoltaic reference devices. Excerpt: “This standard covers photovoltaic reference devices used to determine the electrical performance of photovoltaic cells, modules and arrays under natural and simulated sunlight. It does not cover photovoltaic reference devices for use under concentrated sunlight.” It also adverts to the fact of conformity of RC cell technology with cell technology of modules applied in the field.

Reviewing this information, the requirement is logical as the density spectrum of pyranometers (300 – 2,800 nm) is very different to a crystalline RC / RM (ca. 300 – 1,300 nm). According to that, the PR = 1 (or 100 %) could only reach 1% or 100% in a loss-free PV generator with the insolation reference by RC / RM. Vice versa, PRs using pyranometers as references are lower than the ones based on RC / RM values. The effect of application of both sensors is visible in Graph 1 below.

PR higher than 100%?

The nearer the PR is to 100%, the more effective a plant is operating. PV plants with remarkably overlabelled PV modules show apparently better PRs. Plants with PR 1 (100%) or higher are an exception and only reachable under particularly favorable conditions, like with high insolation values, when cell temperatures are much below STC temperatures. STCs may only sporadically occur in a year, whenever all STCs deviate and exceed (insolation) and undercut (cell temperature) the conditions.

Summary

To draw qualified PR comparisons of different PV plants, plant owners have to grant permission. But this would be an extraordinary exception.

An external exchange of internal information is commonly unacceptable, while an exchange of internal information is often prevented by confidentiality clauses. Therefore, a comparison of PRs of large PV power plants does not take place.

In different countries with different average day temperatures, the following statement is valid: There is a linear correspondence between increasing temperatures and falling PR values, whereby the influence of the wind effect is not considered.

Independent of the above statements, PR factors remain an important indicator of field performance behavior for plant owners and indicators for observing the development of PV module degradation in PV plants.

About the author

Edwin Cunow is the owner of LSPV Consulting. He has more than 33 years experience in the PV business, with a special focus on megawatt-sized PV power plants. He previously held leading positions at Siemens Solar and Shell Solar and, prior to this, worked for 13 years as a freelancer for LE, OE and TDD services. Among others, Cunow is a contributor to the IEA PVPS Task 8 and Task 13, and reviews papers for the EU PVSEC events.

Lắp đặt điện mặt trời Khải Minh Tech

https://ift.tt/2X7bF6x

0906633505

info.khaiminhtech@gmail.com

80/39 Trần Quang Diệu, Phường 14, Quận 3

Lắp đặt điện mặt trời Khải Minh Tech

https://ift.tt/2ZH4TRU

Không có nhận xét nào:

Đăng nhận xét