Research on bifacial solar panel performance has moved performance analysis closer to a standardized practice than ever before. More field tests are under way across the United States and the first waves of data are expected this year. These tests will help standardize a predictive model for bifacial projects that is bankable.

From pv magazine, July edition

As the first round of utility-scale bifacial projects attract financing, developers, lenders, and stakeholders are concerned about energy modeling risk. At the same time, institutional experiments into enhancing albedo have begun, with the goal of raising the bifacial boost from the conservative 10% level now accepted as reliable in the industry, toward a 20% or higher figure. “Bifacial technology with back reflectors represents a paradigm shift in reducing the levelized cost of electricity (LCOE) of solar installations,” asserts Pedro Martin of the Arizona State University’s Photovoltaic Reliability Lab.

These and other experts in bifacial solar research gathered in Albuquerque in May at the the 2019 PV Systems Symposium, co-sponsored by Sandia National Laboratories, CFV Solar Test Laboratory and the Electric Power Research Institute (EPRI) to compare new knowledge gained and to help lay out the roadmap for bifacial performance estimation, installation, and yield gathering. CFV exchanges bifacial test data with Fraunhofer ISE, a global leader in bifacial studies.

The symposium highlighted the joint efforts of Sandia, the U.S. National Renewable Energy Laboratory (NREL) and the University of Iowa, which worked together on a three-year study of bifacial solar. This joint work has focused on three lines, including outdoor bifacial PV performance data, bifacial characterization and rating standards, and performance modeling of bifacial PV systems.

Sandia won a $3 million award from the U.S. Department of Energy’s SunShot National Laboratory Multiyear Partnership (SuNLaMP) for its role in this joint research. NREL also has various grants to study bifacial technology, along with industry support.

The University of Iowa is developing a performance prediction model that uses a reverse ray tracing method, based on Radiance and Python software. The project is funded by the SuNLaMP.

“Bifacial PV systems can sometimes see gains of more than 30% and, combined with tracking, the total electrical gain can be close to 50%, which will reduce LCOE to below $0.02/kWh,” one Sandia report suggests.

Energy gain, equipment savings

The prospect of the bifacial boost is expected to rapidly shift adoption in the industry, especially for tracker-based projects. The International Technology Roadmap for Photovoltaics (ITRPV), produced by the German’s VDMA, predicts that bifacial modules will make up 10% of the world market share of PV modules by 2020, and over 30% by 2028.

“All of the smart panel buyers are purchasing bifacial now,” attests Steven Zhu, the president of Trina Solar USA. Trina has been testing bifacial panels with partners from the United States and China, he notes.

While bifacial panels represent a key technology for the energy yield from albedo capture, tracker technologies, along with smarter inverters, are the supportive vehicles needed to maximize the bifacial gain. Given the much greater granularity of bifacial operational data, compared with monofacial systems, solar designers are finding that the insurance of overbuilding a system to guarantee a given yield is no longer necessary, or at least much reduced.

“Bifacial is not just a boost, it is about using less DC equipment to get there,” says Peter Johnson, senior project engineer at AWS Truepower, the recently acquired advisory part of Underwriters Laboratory. “For bifacial projects, the DC-AC ratio is lower by about 5% to achieve optimal inverter limitation loss,” he says. “A bifacial advantage of 3% to 9% is often realized as a combination of DC capacity cost reduction and energy gain.”

AWS Truepower advocates extensive field testing of albedo measurements for acceptable bifacial performance modeling. On-site albedo and diffuse horizontal measurements can reduce uncertainty about the back-side Plane of Array (POA), AWS found. “A 3% increase (or decrease) in albedo can result in a 1% increase (or decrease) in total POA,” Johnson notes.

Based on its recent field tests of bifacial panels in Illinois and Texas, AWS found that modeled albedo can be 2% to 5% different from measured albedo. In the process, AWS concluded that “the back-side energy contribution may be between 20% and 40% uncertain,” meaning that modeling uncertainty may still be too high to bank on, unless a conservative boost value is assumed.

Bifacial variance

Sandia is facilitating a collaborative group of PV professionals, the PV Performance Modeling Collaborative, or PVPMC. As part of this work, the Sandia team — led by Joshua Stein, a principal investigator at the lab — mounted an initial test field array at its test facility in Albuquerque to gain a sense of where future research needed to be focused. The array consisted of two bifacial and two monofacial modules in two-up formation, with a landscape orientation at a 35 degree tilt.

Among initial results from the field test, the Sandia team found that bifacial gains for the system generally varied between 7% and 16% and were always greater for the bottom row. This difference was likely enhanced by the low sun position during the short test near the time of the winter solstice.

The Sandia team also found that the bifacial gain on clear days was highest in the morning and gradually decreased during the day. This was likely because the bifacial modules were positioned on the east side of the rack, the team observed. “In the morning, the sunlight coming from an angle hits the ground directly under the bifacial modules while the shadow is projected to the west under the monofacial modules,” Stein reports. “In the afternoon, the shadow from the modules is projected under the bifacial side of the array and thus reduces the bifacial gain,” he says.

Enhancing albedo

Perhaps the most forward-looking bifacial field test presented at the symposium was that of the Tempe-based Arizona State University team, which tested three variations of mechanically enhanced albedo fields. The team found that enhanced albedo augmented the bifacial boost by 4% over bifacial panels without the aluminum sheet substrate. Combining a boost of 16% to 20% using no substrate, plus the 14% substrate boost to albedo, yielded a total bifacial boost of between 30% and 34%.

One goal of the ASU research was to help confirm the potential for maintaining a constant energy yield while replacing standard bifacial solar panels, comprised of densely packed 60 cells, with an alternate design of 48 sparsely packed cells-plus-back reflectors.

“Thus we are producing more than half the energy yield of the standard 60 cell bifacial panel with a 48-cell bifacial plus a mounted back reflector, implying fewer cells are needed,” Martin says.

The first part of the ASU research involved outdoor testing of PV modules mounted with different profiles of stationary back reflectors, consisting of aluminum tubes and V-shaped bars on aluminum substrate. The second part of the research focused on the effect of stationary reflectors on shading and array row spacing for bifacial power plants.

The variations in the aluminum substrate included inverted V-shaped vertical columns, and semi-circular vertical columns. The semi-circular columns were composed of aluminum-coated PVC pipe.

Another benefit of the substrate addition was a 40% reduction in the ground cover ratio needed for the fixed yield target, Martin noted. The reduction, coupled with the lower cost of sparsely packed 48-cell bifacial panels, potentially reduces land and material costs of a comparable bifacial system by 50%, apart from the bifacial boost.

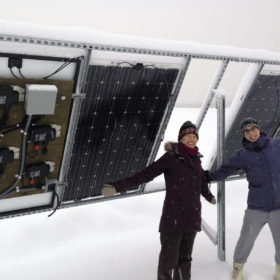

One novel approach to gathering greater naturally available albedo is being studied in Alaska by Sandia, in conjunction with the University of Alaska at Fairbanks, where an array of stationary vertical mounting racks for bifacial panels have been installed.

The Sandia-UAF team, led by Sandia’s Joshua Stein, found that East/West-oriented vertical bifacial arrays can yield up to 20% more energy than traditional designs, with a wider power profile that could better match loads. The team also found that vertical modules seem to shed snow better and collect less soiling material.

Limits to vertical bifacial adoption in the north include a lack of commercial racking solutions for vertical bifacial, a need for optimized field layout to minimize shading, and finalized testing standards for bifacial modules, Stein noted.

Predictive software advances

ASU performed its test measurements with predictive software, including the PVsyst system, the U.S. government open source System Advisor Model (SAM), and Mathwork’s MATLAB Coding. A host of researchers are using multiple software tools to help develop an industry standard that most closely matches predictions with field tests.

NREL is leading the way in validating bifacial software models in SAM, for which a bifacial performance model was recently released. A group there, led by Chris Deline — an electrical engineering researcher — is comparing SAM with PVSyst, currently the leading industry-recognized PV performance modeling tool.

While PVsyst and SAM are commonly referenced standards for predicting bifacial performance, the use of MATLAB is less well known. MATLAB allows matrix manipulations, the plotting of functions and data, implementation of algorithms, creation of user interfaces, and interfacing with programs written in other languages. Python is a base language that several bifacial research projects utilize.

One new software solution introduced at the symposium came from PV Lighthouse. Called SunSolve, it combines ray tracing to the micron level with SPICE, an open-source electronic circuit simulator. SunSolve, a commercial solution for cell and module researchers, is now being extended to solve the annual yield of PV systems. In collaboration with Cypress Creek Renewables, its first test was to simulate bifacial systems with weather data measured by NREL during 2018, solving each system configuration with two billion rays, says Keith McIntosh, director of the company.

Overall, the PV Lighthouse test accounted for the spectral variability of direct and diffuse light, and the spectral and angular dependencies of the ground, torque-tube and module. It also accounted for module temperature and the current mismatch within a module due to non-uniform illumination — particularly a backside problem. The software test also investigated panels at different locations within an array, finding that modules at the edge of arrays show higher current mismatch and higher yield compared to center-of-array modules, McIntosh says.

Among the performance metrics that PV Lighthouse calculated, it was found that cell-to-cell mismatch is about 50% greater for edge modules, and depends strongly on albedo. The ability of SunSolve to account for spectral effects, current mismatch, torque-tube shading and angle of incidence — all detailed to precise granularity levels — makes the software a good companion program to PVsyst, which does not directly solve those factors, he says.

In another recent set of ray-tracing experiments, lead NREL researcher Silvana Ayala and colleagues found that ray-tracing simulations on array edge brightening suggested a 15% to 25% increase in rear irradiance at the ends of tracker rows, but up to 20% loss from center-mounted torque tubes, creating multiple shadows.

Ayala and co-researchers used NREL’s V3 Bifacial Radiance software to measure additional facets of bifacial performance, including table height and torque tube clearance, table separation over the torque tube, differentiation of four different geometric shapes of torque tubes — to encompass all market offerings, and hourly cumulative tracking, detailed in her presentation at the symposium.

One new bifacial application analyzed by Ayala and team was the performance of bifacial panels on carports or canopies. The analysis was sensitive enough to detect the position of vehicles under the canopy, and compute the difference in albedo as cars were moved in or out, she notes.

DNV GL is now working to optimize its SolarFarmer software to extend bifacial performance from fixed tilt to trackers by the end of this year, says Mark Mikofski, a principal engineer at the company. DNV GL’s work on fixed-tilt bifacials showed, among other things, that bifacial panels performed better at a 30 degree tilt, while monofacial panels perform best at 25 degrees.

SolarFarmer is a PV plant design product that includes a full 3D shading and calculation model, handling complex terrain and shading obstacles, DNV GL says.

Lắp đặt điện mặt trời Khải Minh Tech

https://ift.tt/2X7bF6x

0906633505

info.khaiminhtech@gmail.com

80/39 Trần Quang Diệu, Phường 14, Quận 3

Lắp đặt điện mặt trời Khải Minh Tech

https://ift.tt/2ZH4TRU

Không có nhận xét nào:

Đăng nhận xét